Waspaloy - Aloyi Wolimba Wogwiritsidwa Ntchito Pakutentha Kwambiri

| Aloyi | chinthu | C | Si | Mn | S | P | Mo | Cr | Al | Ti | Fe | Cu | B | Zr |

| Waspaloy | Ochepera | 0.02 | 3.5 | 18.0 | 1.2 | 2.75 | 0.003 | 0.02 | ||||||

| Max | 0.10 | 0.75 | 1.0 | 0.03 | 0.03 | 5.0 | 21.0 | 1.6 | 3.25 | 2.0 | 0.5 | 0.01 | 0.12 | |

| zina | Co:12.0~15.0,Ni:balance | |||||||||||||

| Mkhalidwe wa Aolly | Kulimba kwamakokedwe RmOchepera Mpa | Mphamvu yobereka RP 0.2Mpa yaing'ono | Kutalikitsa A 5Ochepera% | Kuchepetsa wa Chigawo,mphindi, % | Kuuma kwa Brinell HB |

| yankho + kukhazikika + kuuma kwa mvula | 1100 | 760 | 15 | 18 | 310 |

| Kuchulukanag/cm3 | Malo Osungunuka℃ |

| 8.19 | 1330~1360 |

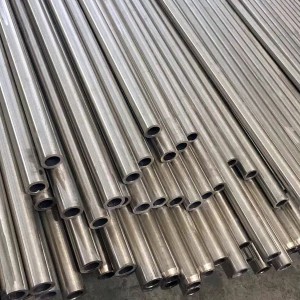

Ndodo, Mipiringidzo, Waya ndi Zopangira- ASTM B 637, ISO 9723, ISO 9724, ISO 9725, SAE AMS 5704, SAE AMS 5706,

Mbale, Chipepala ndi Mzere -SAE AMS 5544

Lembani uthenga wanu apa ndipo mutitumizireni